How to Test a Vacuum Pump with Bobcat Industrial Air Services

At Bobcat Industrial Air Services in Nashville, TN, we understand that regular testing of vacuum pumps is essential to maintain peak performance, prolong equipment life, and avoid costly downtime. Whether your vacuum pump powers critical lab experiments or industrial processes, implementing a robust testing routine is vital to catching issues early and ensuring reliable operation.

Why Test Your Vacuum Pump Regularly?

Vacuum pumps often operate continuously and rely on wearable parts to maintain performance. Without regular testing, minor issues can escalate into significant problems, including:

Increased energy consumption

Damage to internal components

Costly repairs or replacements

Catastrophic failure during critical operations

By testing your pumps, you ensure they operate efficiently, extend their lifespan, and avoid unexpected breakdowns that can disrupt essential operations.

How Often Should You Test Your Pump?

The frequency of vacuum pump testing depends on:

Application criticality: Pumps in hospitals or labs should be tested frequently due to the high stakes of failure.

Operating conditions: Pumps in extreme temperatures, dusty environments, or running at maximum capacity require more frequent checks.

Usage: High-use pumps should be tested more often than those used intermittently.

Bobcat Industrial Air Services recommends testing pumps after a set number of operating hours based on the manufacturer’s guidelines and specific environmental factors.

Benefits of Regular Vacuum Pump Testing

Preventative Maintenance: Catching minor leaks, wear, or overheating early prevents more serious issues.

Cost Savings: Proper testing avoids energy waste and reduces the need for emergency repairs.

Optimal Performance: Testing ensures your pump operates at its rated vacuum levels and flow capacity.

Prolonged Equipment Life: Routine checks help you perform maintenance tasks like oil changes and filter replacements on time.

How to Test Your Vacuum Pump

Manual Inspection

Start with a hands-on approach to detect visible and audible signs of wear:

Visual Check: Inspect hoses, power cords, and pump housing for damage.

Oil Inspection: For oil-lubricated pumps, check the oil level and look for signs of burning, such as darkened oil or a burned odor.

Filter Check: Ensure external or integrated filters are clean and unclogged. Replace filters if necessary.

Run the Pump: Listen for unusual noises, feel for vibrations, and check the vacuum pressure gauge. Ensure the pump reaches its rated vacuum level by measuring close to the inlet.

Diagnostic Testing

A diagnostic test provides more precise insights into your pump’s health:

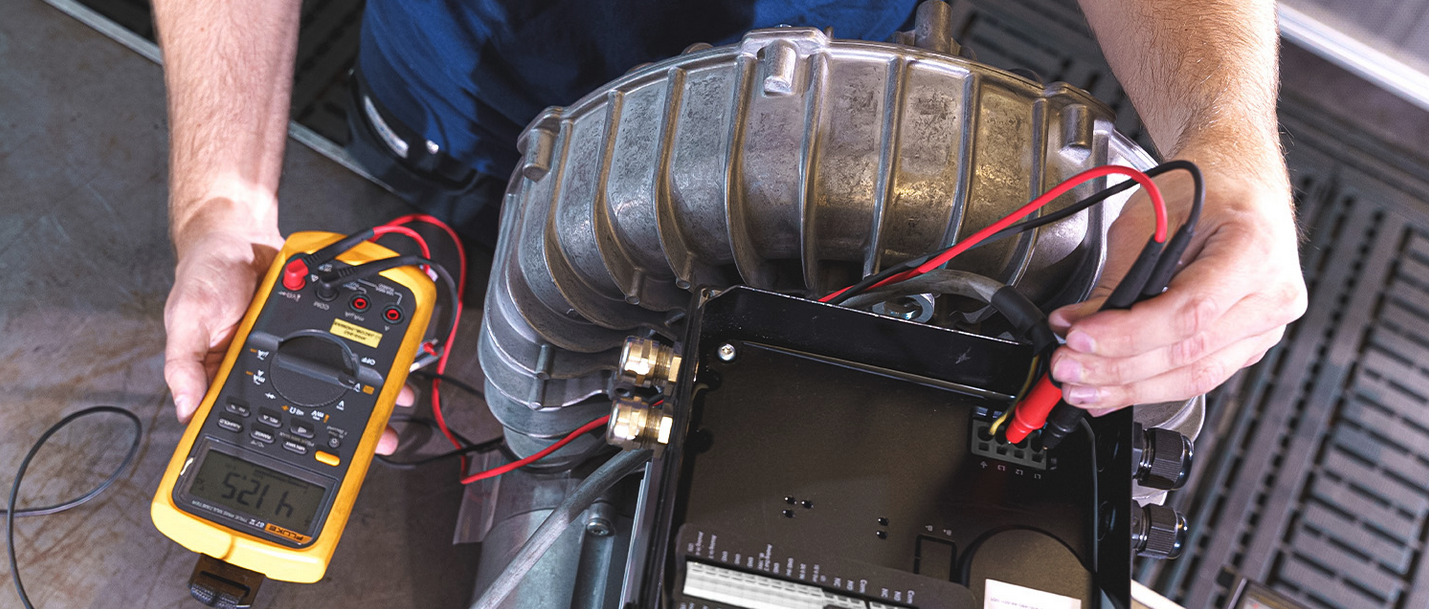

Gather Tools: Vacuum gauge, flat plate or adapter, clamp amp probe, and any necessary hand tools.

Isolate the Pump: Disconnect it from the system.

Connect the Gauge: Attach it to the inlet port.

Test the Vacuum Level: Run the pump and compare the vacuum reading to the rated specs on the pump’s plate.

Check Amperage: Measure the pump’s amperage with a probe. Ensure it is at or below the full load amps (FLA) listed on the motor tag.

When to Call the Experts

Even with routine testing, some issues require professional attention. At Bobcat Industrial Air Services, we offer comprehensive vacuum pump diagnostics and maintenance services. Our team can help:

Address abnormal readings, such as excessive amperage or reduced vacuum levels.

Perform advanced repairs for overheating or worn components.

Optimize your system for improved performance and efficiency.

Why Choose Bobcat Industrial Air Services?

Bobcat Industrial Air Services in Nashville, TN, is your trusted partner for all things vacuum pump-related. We provide:

Expert Guidance: From testing and diagnostics to repairs, our team ensures your pumps are in peak condition.

Top-Quality Products: We offer industry-leading vacuum pump systems tailored to your needs.

Preventative Maintenance Programs: Stay ahead of issues with scheduled testing and servicing.

Contact Us Today

Ensure your vacuum pumps perform reliably and efficiently with help from Bobcat Industrial Air Services. Contact us for testing support, maintenance, and expert advice to keep your operations running smoothly.